Terminal Automation gives you complete control of loading and off-loading of product at your terminal or depot. Loading via ship, pipeline, rail car or road tanker can be automated through the appropriate use of loading computers, meters and/or weighbridges which can be interfaced to and driven by MHT’s SmartTAS Terminal Automation System. Where automated metering systems are not available, loading transactions can be manually entered into the central Stock Management System from meter tickets or other Bill of Lading (BOL) documents provided.

Physical stocks can be reconciled with transactional records of receipts and loads allowing any losses or gains to be quickly identified and accounted for. Launched in 2011, SmartTAS terminal automation software is a scalable solution which can communicate directly with a single loading skid at a typical depot or multiple gantries at larger oil terminals.

MHT’s systems are provided with a wide range of interfaces offering connectivity to most makes of loading computers, entry/exit controllers and weighbridges. Our SmartTAS Terminal Automation Software integrates to devices from all leading manufacturers, giving our customers the flexibility to use the Loading Computers, Access Control Units and Weighbridges that give the best fit for their terminal or depot. Using SmartTAS alongside our VTW Tank Gauging System and Bookstock Stock Reconciliation and Accounting Module can provide your terminal with a complete overview of all stocks, receipts, loads and transfers.

benefits

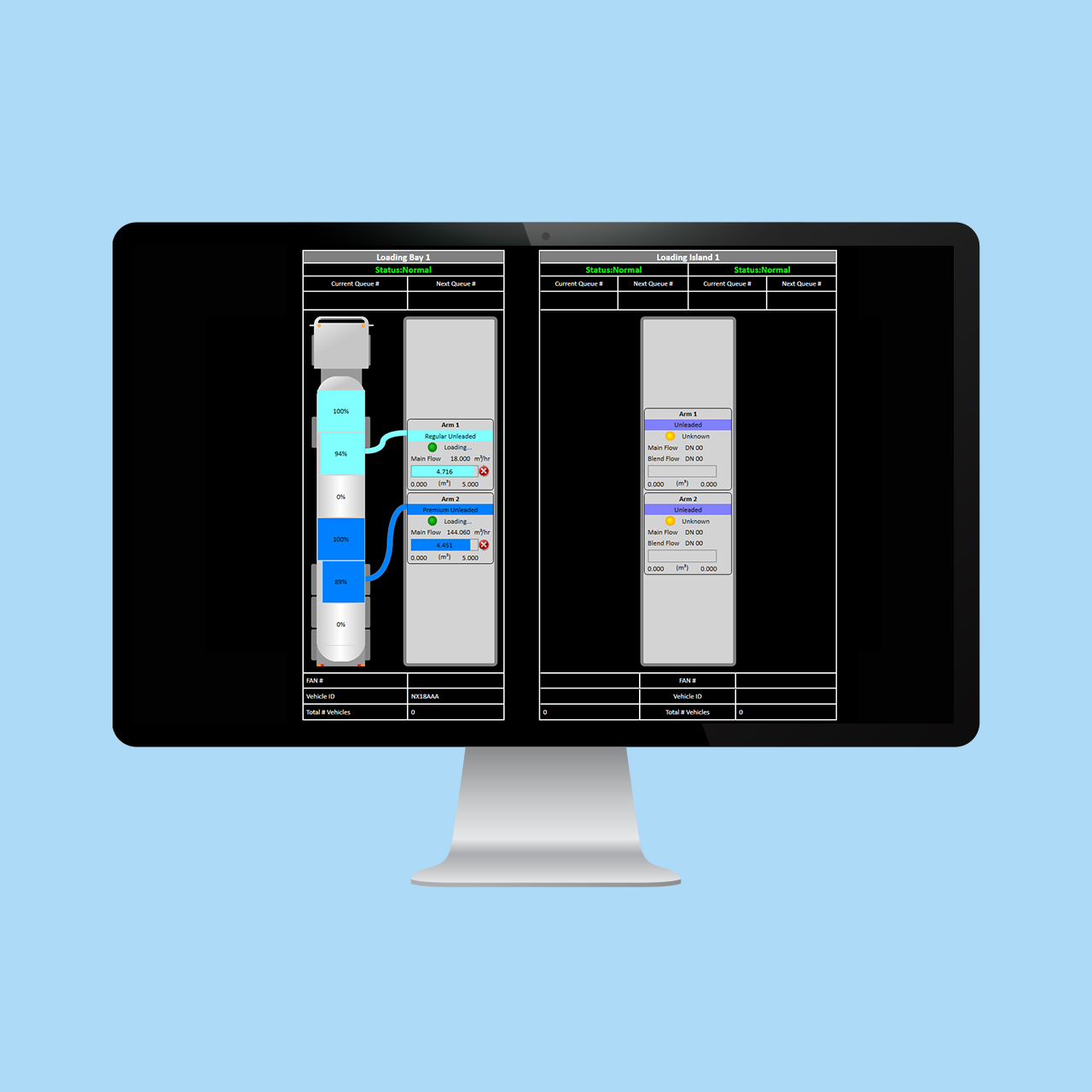

SmartTAS is a Windows-based total terminal management system designed to meet the requirements of depots and terminals. Interfacing to most vendor devices used for access control, rack loading computers, and weighbridges, SmartTAS provides total management control of product movement and a secure and controlled loading and off-loading procedure for all movement types. SmartTAS also enables total site control and overview, allowing operators to access details of all gantries, loading arms, vehicles, drivers, and product in use on-site.

- Terminal Automation system.

- Windows 10 / Windows Server 2019 compatible.

- Open system for access control units, loading computers, and weighbridges.

- Configurable to easily accommodate different workflow procedures.

- Interfaces with VTW for real-time physical stock data.

- BookStock Stock Reconciliation module available.

- Vehicle queuing.

- Self-service Kiosk

- Product UN Hazard Codes are now fully editable, customers can change the languages presented and add new hazard codes to fit their operations

- Addresses are now first-class data items in TAS

- seal details can be entered at the bay, and support for the Danload DL8000 in a multi-arm deployment

- Integration to 3rd party systems is now possible through a new built-in OPC UA service

- SmartTAS can publish live loading bay information, including transaction data such as driver names, order numbers, and vehicle registrations

- Prepare documentation for vehicles that have been manually “topped off” or moved to another loading bay to complete a load

BookStock is a bulk liquid stock accounting application on suitable for sites handling petroleum products and other bulk liquids. The BookStock application is a scalable system suitable for single or multi-user environments. It features built-in multi-site capability, allowing the management of many sites by one central stock accounting team. It can operate in a purely manual setting where all data is entered manually, or it can be connected to a range of automation systems for collecting data automatically. Available as a module alongside SmartTAS.

- Bulk liquid stock accounting application.

- Windows 10 / Windows Server 2019 compatible.

- Seamless integration with VTW and SmartTAS.

- Suitable for sites handling petroleum products and other bulk liquids.

- Performs calculations to API/ASTM standards.

- Comprehensive, customisable reports.

- At the month end the losses and gains can be attributed automatically from Co-mingled storage.

- Aviation capabilities such as hydrant movements, average density and temperature figures and Sarbanes-Oxley compliant reporting.

- Reports on demand – All reports are designed with Crystal Reports although

other reporting tools can be supported. - Security – A security system is in place which permits users to set

up accounts for each user and to assign each user their own set of rights - Remote access – Remote Access to the BookStock system can be provided

via the internet. - Interfacing – BookStock’s open database architecture and the use of modern communication on technologies enable data to be transferred to other systems very easily.

- Supports different architecture.

- Special applications designed for handling hazardous waste.

hardware

RMS2

- RMS2 integrates with the VTW Tank Gauging System to automatically announce alarms over a site radio system.

- requires an Ethernet connection to the tank gauging system and

connection to a radio base station. - Virtualisation and high availability.

- Interfaces with VTW for real-time physical stock data.

- Fail-safe component.

DATASHEETS

SMARTTAS TERMINAL AUTOMATION SOFTWARE

SmartTAS is a Windows-based total terminal management system designed to meet the requirements of depots and terminals. SmartTAS provides total management control of product movement and a secure and controlled loading and off-loading procedure for all movement types.

rms2

MHT Technology Ltd’s new radio messaging system ‘RMS2’ was launched in March 2020, enabling digital tank gauging systems to send timely warning notifications using existing radio systems.

bookstock

BookStock is a bulk liquid stock accounting application on suitable for sites handling petroleum products and other bulk liquids. The BookStock application is a scalable system suitable for single or multi-user environments. It features built-in multi-site capability, allowing the management of many sites by one central stock accounting team.

What is a Terminal Automation System?

What is a Terminal Management System?

Terminal managers ensure that the operations undertaken at the site are fulfilled efficiently and safely. To achieve this many sites employ a Terminal Management System of which a Terminal Automation System and a Tank Farm Management System may be a part.