Overview

The Mini Receiver from MHT Technology is a small integrated tank gauging and tank inventory management system utilising the latest Windows 10 IoT embedded technology. The Mini Receiver consolidates devices from multiple vendors into a single unit for cost-effective bulk liquid storage. Learn more about our scalable, open solution suitable for depots, terminals, and refineries. The Mini Receiver is designed to keep our customer’s site’s running as efficient and cost-effective as possible.

It is a smartly compact tank gauging and tank inventory management system, suited for tank farms of any size using various communication protocols for their installed field devices. MHT’s Mini Receiver ‘mark 1’ was first launched in 2006, revolutionising the industry by enabling sites to have more freedom in their suppliers and eliminating ‘vendor lock-in.’ Since then we have continued to innovate by developing the latest version ‘the mark 3’ in 2013 which directly interfaces up to 400 devices simultaneously. Should a site’s tank gauging system be unable to display tank gauging information then the Mini Receiver screen allows some control over the site.

The Mini Receiver comes with support for 4, 12 and 20 ports that can serve as host or field ports, full inventory calculations to API/ASTM standards, an OPC Data Access Server and much more. It features a full graphical 7” LCD display with touch screen technology showing live and calculated tank data allowing control over the field instrumentation as well as alarm and events notification.

In addition to being a small tank inventory management system, it can be used as a foreign device gateway to higher-level DCS and site-wide business information systems by emulating older proprietary protocols, as well as flexible protocols such as Modbus and OPC DA.

benefits

Different gauge commands

Networking functionality

Configuration

Reliability

Service monitoring

Flexibility

Communication options

Compatability

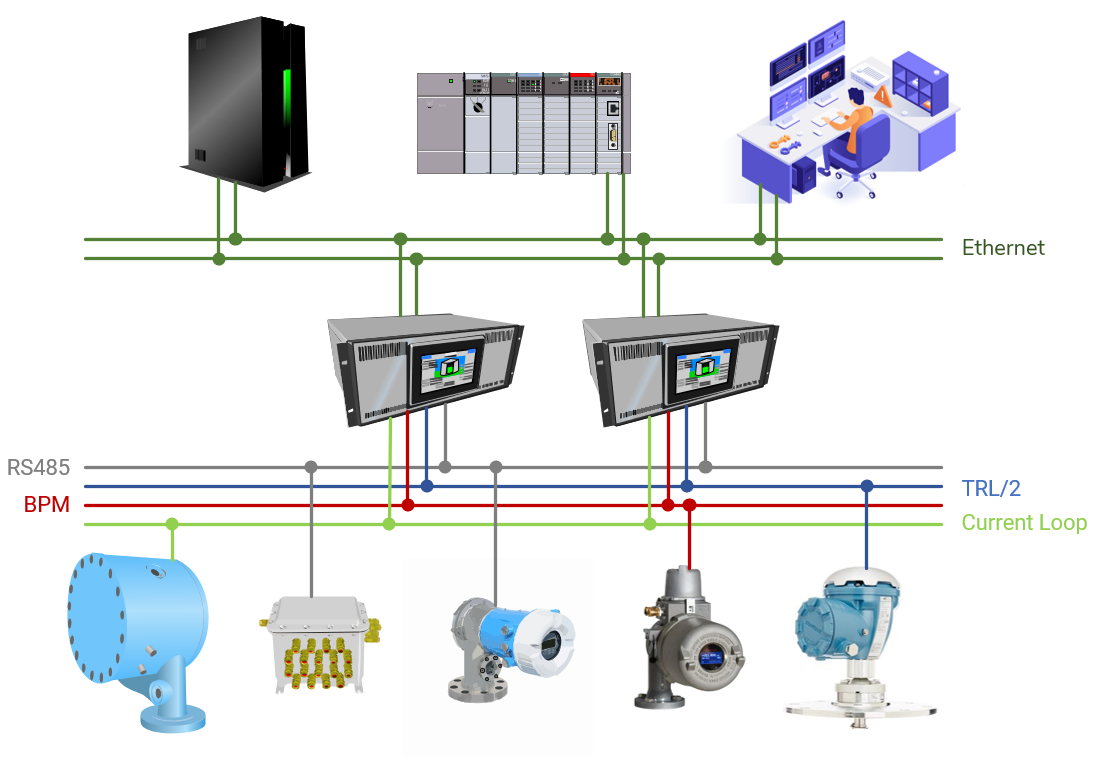

System Architecture

• Standalone station

• Client-Server system

• Distributed multi-site systems

• Modbus and OPC interfaces to sitewide

distributed control systems and other

business systems

• Fieldbus and device-independent

The Mini Receiver has 2 Ethernet ports, which can be configured to support redundant Ethernet or as separate networks. Devices in a redundant configuration may either use one of these ports to synchronise themselves or a pair of serial ports. The performance of the Mini Receiver can be monitored via a built-in SNMP interface allowing access to statistics such as the number of communication faults on a field bus, when and why redundant switchovers have occurred.

The requested gauge commands can be invoked from the display:-

•Stow/Lock

•Unstow/Unlock

•Water Dip

Key Features

- Windows 10 IoT embedded system

- Full-colour graphical LCD Interface with Touch Screen

- Inventory calculations to API/ASTM Standards

- Available with 4, 12 or 20 communication ports configurable as host or field interfaces

- Dual Ethernet port

- Field interfaces for most makes of tank gauge

- Up to 256 tanks

find out how THE MINI RECEIVER can help your site today

DATASHEETS

Mini RECEIVER TANK Gauging HARDWARE Mark 3

The Mini Receiver consolidates devices from multiple vendors into a single unit for cost-effective bulk liquid storage.