Overview

The Gauge Emulator is an intelligent protocol converter and data concentrator that emulates multiple gauges and integrates seamlessly into existing systems. There are a number of reasons why a site may need to replace a tank gauging device. Previously, the site would have to replace like-for-like due to infrastructure constraints, but this is now no longer the case. The Gauge Emulator allows the seamless integration of vendor A’s tank gauges into an existing infrastructure intended only for vendor B’s equipment, eliminating ‘vendor lock-in’ and giving the freedom of choice back to the site.

Field ports

As standard, the unit is supplied with two field ports, one acts as a host to the foreign device and the other replicates the field bus of the existing tank gauging system and emulates the behaviour of the other gauges. The field ports are plug-in units and available with a number of different electrical interfaces allowing connection to most of the major proprietary and open field bus technologies available within the tank gauging industry market. The flexibility of the design permits the device to be re-deployed once a loop is converted. The device can also serve as a host for multiple gauges, allowing a single gauge emulator to provide a interface during a rolling programme of tank refurbishment and gauge replacement.

A second field port can be included so that a redundant pair of host interfaces can be emulated, allowing gauges with a single host output to be deployed where additional resilience in the field cabling is required.

data access

The unit polls the foreign device continually for data maintaining an in-memory real-time database. It also services the field bus master for data on demand taking data from the real-time database as required. In addition, the system will translate any gauge commands supported by the host system and the foreign device.

Configuration

The Gauge Emulator can be installed with ease due to its ‘plug & play’ capability. A serial communications port is provided for configuration and diagnostic use. Where the host communications interface is Modbus, the device allows configuration remotely over the bus.

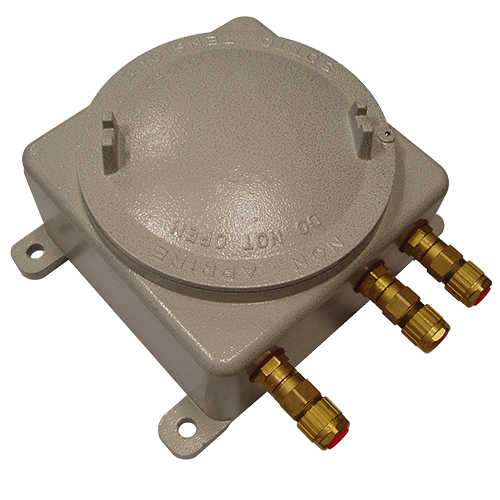

Gauge Emulator, Ex

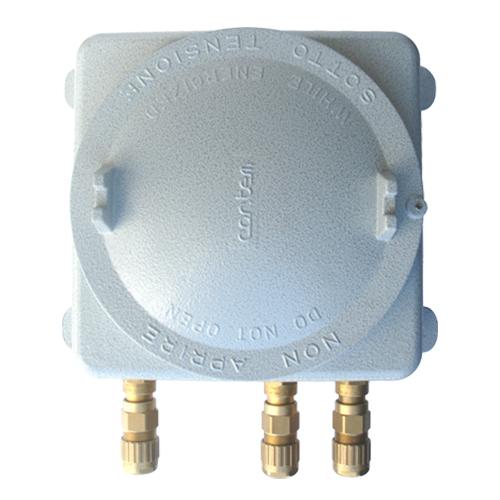

Gauge Emulator, non-Ex

Gauge Emulator, front view

Key features

- Allows tank gauges to communicate effectively within any vendor’s existing system.

- Easy ‘plug & play’ installation process.

- Ability to convert most vendor protocols.

- Concentrate data gathered from several connected gauges locally within one field device.

- Releases any obligation to use only one supplier.

- MHT offers bespoke gauge emulation, customising a Gauge Emulator to fit unique vendor protocols.

- ATEX and IECEx Hazardous Area Zone 1 certified.

Compatible gauge manufacturers

- Endress+Hauser

- Honeywell Enraf

- Whessoe

- ‘Saab’ Emerson/Rosemount

- Motherwell

- Varec

- L&J

- Scientific Instruments

- HART®

benefits

REDUNDANCY

cost savings

Improve site management

SAFETY

![]() IS variants of the Gauge Emulator comply with ATEX and IECEx Zone 1 requirements. Produced in the UK from a manufacturer with over 15 years experience of in designing and manufacturing solutions for explosive atmospheres.

IS variants of the Gauge Emulator comply with ATEX and IECEx Zone 1 requirements. Produced in the UK from a manufacturer with over 15 years experience of in designing and manufacturing solutions for explosive atmospheres.

Typical application: RENEWAL PROGRAMME

You want to replace your old unsupported gauges with new gauges from a different vendor, but you can’t afford to put all the tanks on one loop out of service for the time it takes to install perhaps 10 or 12 level gauges and temperature probes. Perhaps you want to avoid a large upfront capital expense.

Installing a Gauge Emulator allows the gauges to be replaced one-by-one allowing you to plan the renewal programme to fit around your operations, allowing your site to continue to earn its keep while you simultaneously improve it, and the Gauge Emulator pays for itself.

Typical application: GAUGE REPLACEMENT

Consider the situation whereby certain gauges, supplied by vendor 1, were not performing to expectations. The ideal solution may be to replace these devices with alternate products from vendor 2, even though they are unlikely to be compatible. Using a Gauge Emulator eliminates vendor incompatibility, allowing the seamless introduction of different devices into the existing system.

Redundant Field bus systems

In applications where dual redundant field bus ports are required, some leading gauge manufacturers only provide a single field bus output. The Gauge Emulator can be used to solve this problem, by using a host port to poll the gauge and two client ports to service requests from the redundant field bus.

find out how THE gauge emulator can help your site today

DATASHEETS

Gauge emulator

Intelligent protocol converter and data concentrator that emulates multiple gauges and integrates seamlessly into existing systems.