Overview

MHT Technology Ltd’s VTW software is a scalable tank gauging and inventory management solution designed to adapt to any site requirement regardless of size or budget. The launch of VTW in 1994 was a landmark achievement for the industry, arriving as the first Windows-based tank farm system. We continue to develop the software in-house, digitally transforming sites, saving our customers money, and improving safety. Our tank gauging system is scalable, customisable and compatible with major vendors’ level gauges; including Honeywell Enraf, Emerson/Saab, Varec, Whessoe and Endress+Hauser.

From the very start, VTW was designed with the specific intention to be device and gauge vendor-independent. This means that both existing and newly purchased instruments, regardless of vendor, can be seamlessly integrated into a single solution. With over 600 installations worldwide, our customers vary from independent bulk liquid storage companies to refineries, to networks of manned and unmanned oil depots. VTW Tank Gauging Software gives operators the tools they need to ensure the safe storage and movement of products, whilst optimising the use of tank capacity and improving efficiency.

benefits

Real-time and historical data

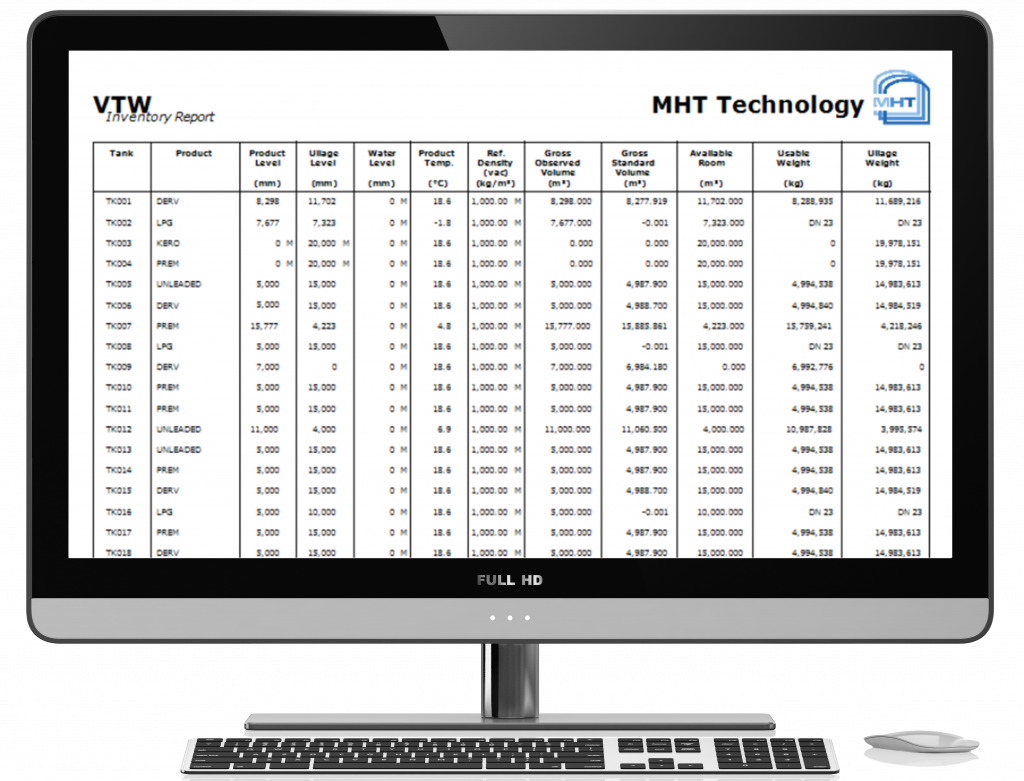

Reports On Demand

Redundant systems

SCADA Designer

alarm management

Radio Annunciation of Alarms

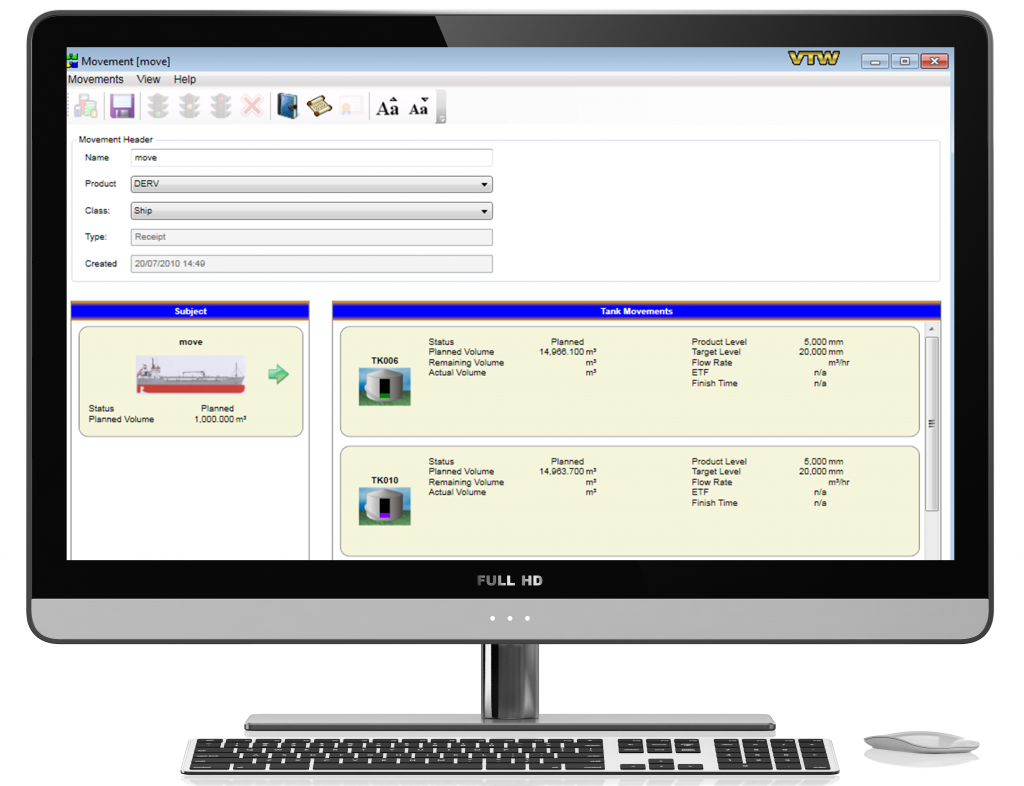

movements package

Business Information Server

software features

VTW has undergone a process of continual innovation over 25 years, often incorporating feedback and requests from the customers that use it. All our software is designed, developed, and tested in-house by a team of bulk liquid storage and handling experts.

The latest version of VTW includes the core features of a homepage overview and grid view, data trending, movements, security and data integrity, SCADA screens, alarm/event viewer, audit trails, RSM2, HM21 inventory calculations and the new Business Information Server.

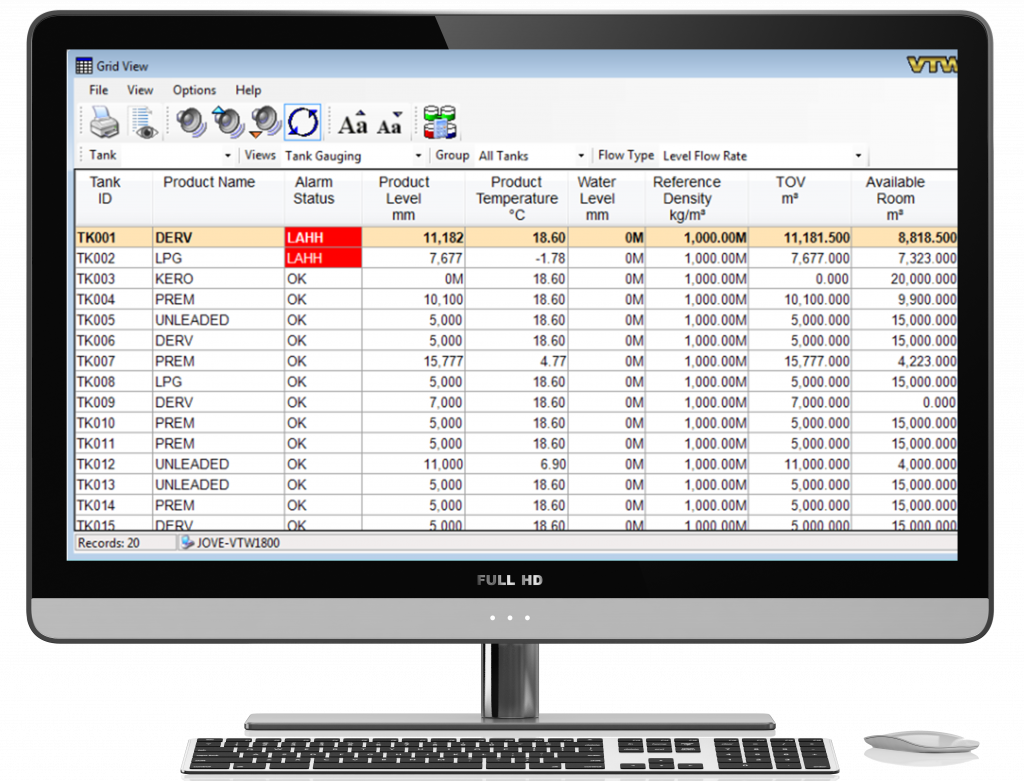

Homepage Overview and Grid View

VTW provides a comprehensive overview of the whole tank farm, with individual windows for each tank. They display a configurable summary of all its data with associated icon shortcuts of all features. The Grid View provides a more traditional spreadsheet overview, displaying a tabular view of data for all tanks. The rows in the grid represent individual tanks and the columns represent data. Standard templates are provided, although additional views can be easily configured.

data trending

All live and calculated data is continuously trended based upon a user-defined strategy. This provides the operator with both a real-time and historical view of individual gauge activity. The information can be viewed in graphical format or exported to Excel if required. The graphical trend viewer allows trends to be overlaid on top of each other either to compare values from the same source or to compare data from different sources. The trend feature is ideal for analysing historical events or incidents, and can also be used for other tasks such as leak detection or checking tank movements.

Movements

The movements package provides operators with the tools necessary to manage the safe movement of product between locations. Movements are configured according to site policies, for example, maximum/minimum safe operating levels, predetermined flow rates, and user permissions. Operators can then set up and safely perform a product movement, confident that it will comply with site operating policy. During the movement, the operators can monitor the progress via site customisable displays showing tank flow rate, estimated finish time, remaining and actual volumes, while the system will generate alarms at specifically configured levels. All movement data is recorded within the database and can be visualised in reports and certificates.

security and data integrity

The system is protected by a comprehensive and adaptable security model that is designed to comply with specific security measures in use on different sites. Usernames and passwords are assigned to each user, and users are assigned a user group with a set of privileges. VTW allows you to carry out complex tasks with the reassurance of high-security standards.

The system administrator can determine which features of the system a particular group has access to and the degree of access they are authorised. Backup scheduling facility: providing backups of SQL databases, registry settings and files, configured at scheduled intervals as required.

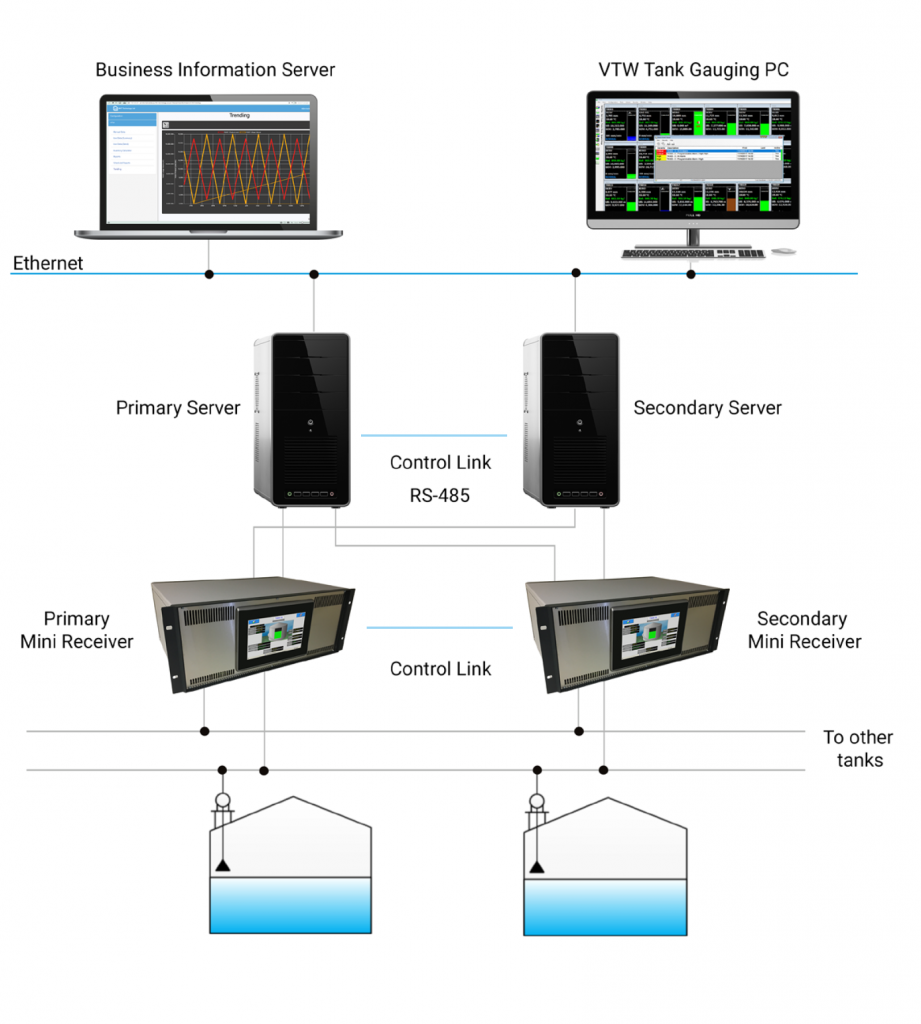

Redundancy can be synchronized, regardless of the system size. Whether a simple redundant operator station for small systems or a pair of redundant servers for client-server architecture, we can provide a system with high availability.

scada screens

The SCADA screens can be customised to incorporate simple process and plant control, for example, the interrogation of a pump and valve control. The close link of these systems lends itself to more secure and integrated control functions, mirroring real-life visualisation with operational management within VTW.

Redundant Systems

The use of a redundant system automatically protects against hardware or operating system failure. Redundancy is available at the server, data concentrator and ethernet level. A redundant system allows operators to continue working without interruption and the need to seek immediate technical support.

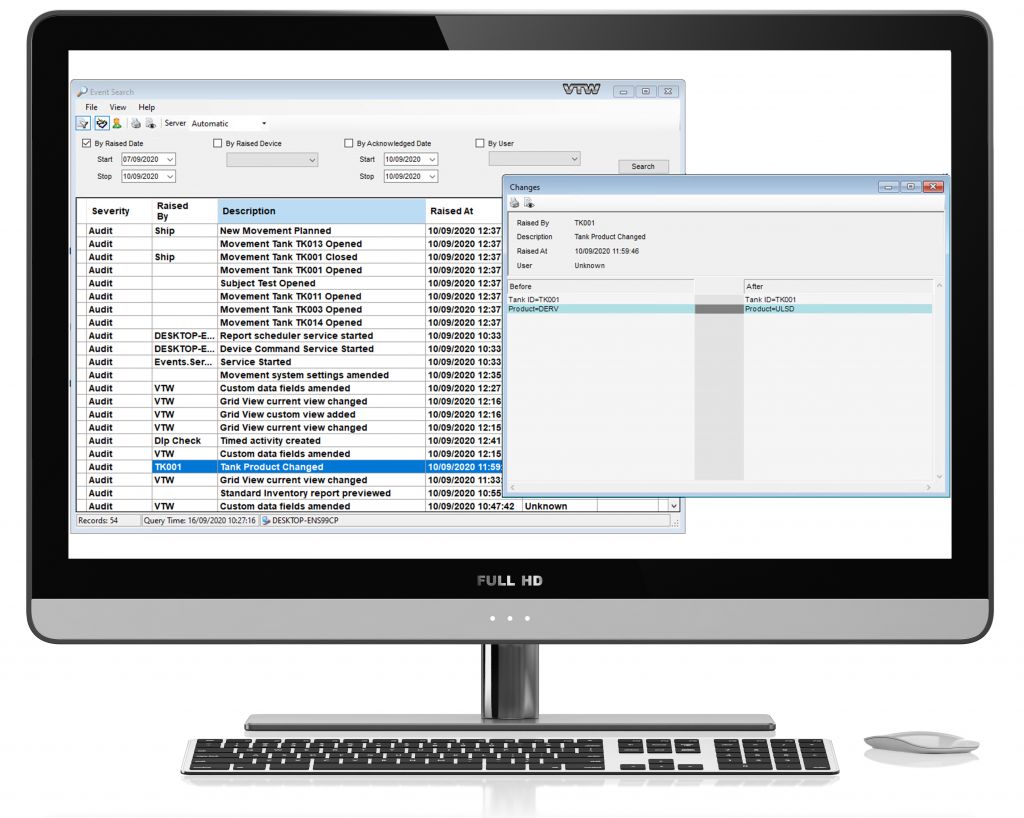

Alarms, Event Viewer and Audit Trails

Each alarm in VTW is configurable with designated severity levels and auditory annunciations. In the event of an emergency, you will be warned well in advance to avoid any costly and dangerous incidents. VTW alarms can be further customised to suit the particular requirements of the site, for example, ‘critical’ alarms may require a logged reason before acknowledgement, whereas ‘low’ alarms can be silenced with only a visual indication.

All alarms are customisable through a graphical user interface, allowing names, descriptions, and annunciation of the messages to be tailored depending on the terminology used at each site. The alarm summary screen is clear, concise, and ideal for handover periods between operators. All alarms are logged to the database, detailing the cause, date/time, and the user that acknowledged it.

The audit trail automatically records all changes that occur to the system and all activities are recorded allowing managers to ensure that correct operating procedures are being followed. This is invaluable for analysis and determining the status of the system pre and post-incident.

business information server

Site managers now have the ability to view data away from their site, allowing business decisions to be made instantly across multiple devices. It provides staff with a secure log-in which allows tank gauging data to be viewed using a standard web browser and provides the ability to reconcile data back to head office. The BIS can be deployed on a different network to the tank gauging system.

RMS2

The new Radio Messenger System ‘RMS2’ from MHT Technology is based

on years of experience in the field. This is a licensable option within our VTW

tank gauging software. You can now support tank farmworkers away from the control room with audio messages and warnings transmitted over site radios. The system can be used with both virtualised and redundant servers.

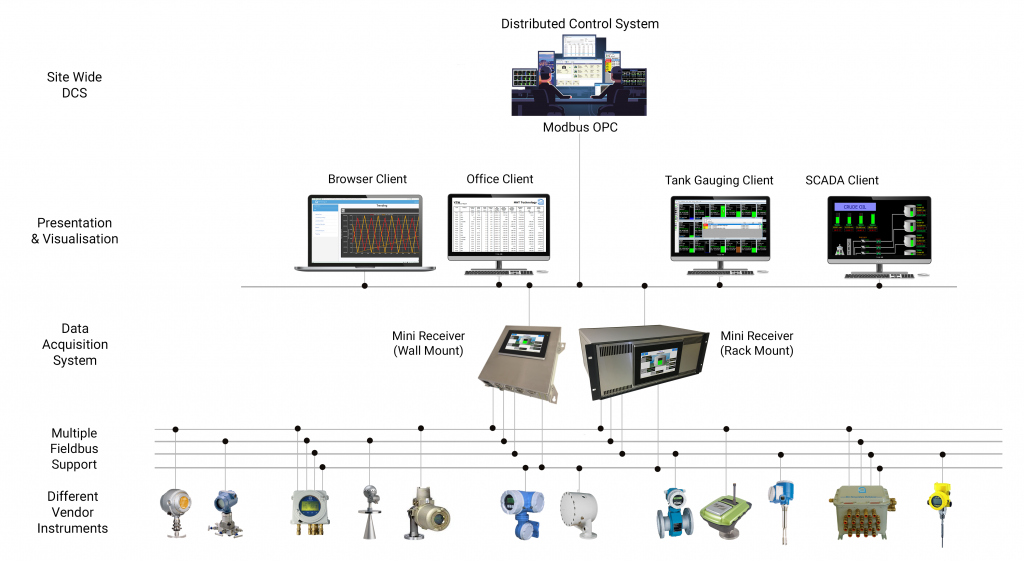

System Architecture

• Standalone station

• Client-Server system

• Distributed multi-site systems

• Modbus and OPC interfaces to sitewide

distributed control systems and other

business systems

• Fieldbus and device-independent

find out how vtw can help your site today

DATASHEETS

VTW Tank Gauging Software 18.3.3

With over 600 installations worldwide VTW is a scalable tank gauging and inventory management solution designed to adapt to any site requirement regardless of size or budget.