Overview

The tools for operators to manage the safe movement of product between locations are provided by the Movements packages in VTW. Within VTW there are two packages: “Simple” and “Full” Movements. “Simple” Movements is free on all licenses, the second “Full” Movements is a paid-for optional extra. In this article, MHT goes deeper to discuss the differences between the two and why Movements is an important consideration when choosing a tank gauging system.

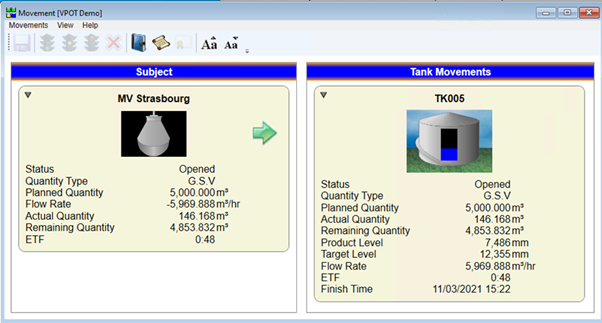

Operators are guided to set up a product movement, confident that it will comply with site operating policy. During the movement, the operators can monitor the progress via site customisable displays showing tank flow rate, estimated finish time, remaining and actual volumes, while the system will generate alerts at specifically configured points. All movement data is recorded within the database and can be visualised in reports and certificates.

A site’s policies for the safe movement of products are defined by those with responsibility for its safety. Maximum/minimum safe operating levels, maximum safe flow rates, and conferring authority on people to carry out certain operations are common decisions that are made when creating the policies. Movements make keeping to those policies easier by ensuring that operators plan and monitor progress.

simple Movements

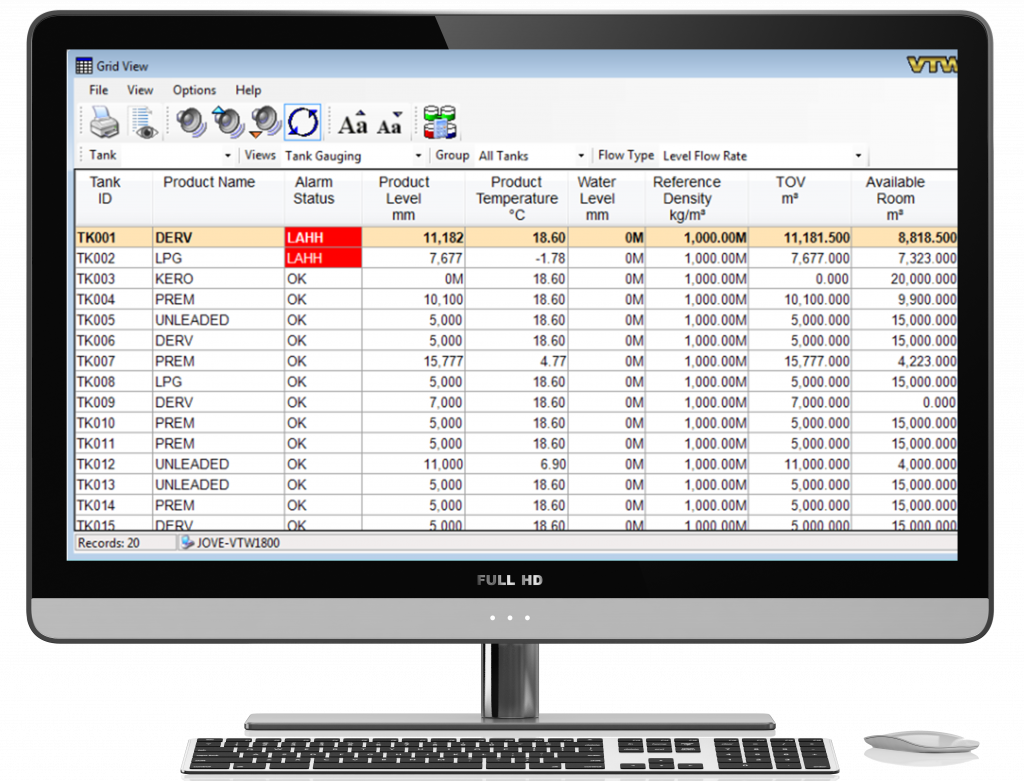

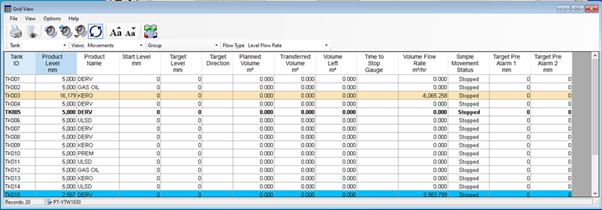

Access to the simple movement is normally made via the Grid View, customised views can be designed to optimise the information to the site’s needs, however, a Movements view is provided during installation for use as a starting point.

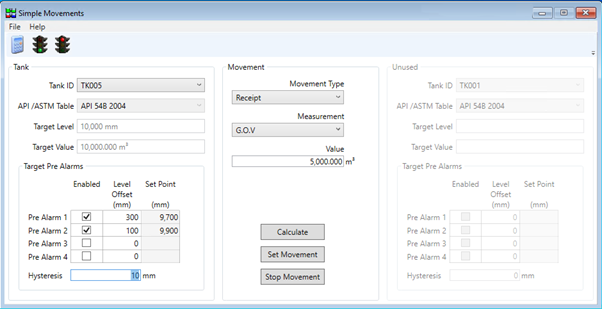

To configure a movement the operator enters the desired outcome from the movement, he may want to empty the tank, ship a certain quantity of product, or fill it to defined level. The movement calculator uses the current tank readings as a starting point and calculates the resulting target level from the outcome according to the tank’s inventory settings. At this stage he can set pre-alarm levels to provide prompts as the movement near completion.

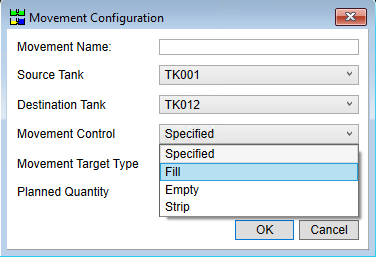

Tank to tank transfers can also be configured, with the calculation results being applied to both the source and destination at the same time.

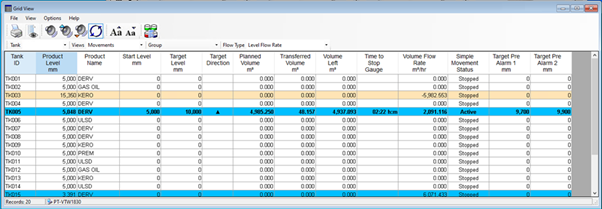

When the movement details are ready, the operator clicks “Set Movement” button to start the movement. At this point unauthorised movement (leak) detection is disabled automatically. During the movement the information on the progress of the movement is calculated and shown on the grid view screen.

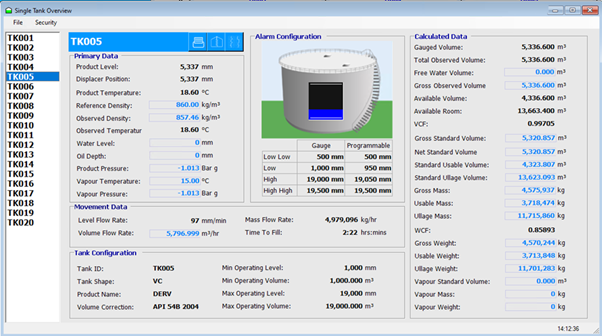

This information can also be displayed on the Single Tank Overview, the standard layout is shown below – but this can be customised to suit a site’s requirements.

Pre-alarms are sounded when the tank levels are within a certain distance of the target to alert the operators.

full Movements

Simple Movements leaves a lot to the operators’ judgement and experience, where the Full Movements comes in to its own is the ability for supervisors to place limits on their activities and promote safe methods of working. For instance, should a movement be planned that causes a tank to be filled beyond the Safe Maximum Fill, on full movements the operator can be:

- Prevented from planning such a movement

- Allowed to plan, but prevented from starting such a movement

- Allowed to start a movement providing they have supervisor privileges on the system

There is a work flow for movements in Full Movements, which sees a movement progress from planned, to open, to finished and there are checks at each stage to prevent unsafe work. Movements can be paused and restarted in Full Movements allowing temporary stops on operations to be restarted from where they left off.

The configuration and setup of Full Movements can be quite daunting, many sites have to spend time reviewing operational policies, and formalising the use of Full Movements in order to get the best out of it.

The rewards for doing so are uniformity in their operators’ understanding of “How we work” as well as making it easier for them to follow the rules than work around them.

Movement Summary

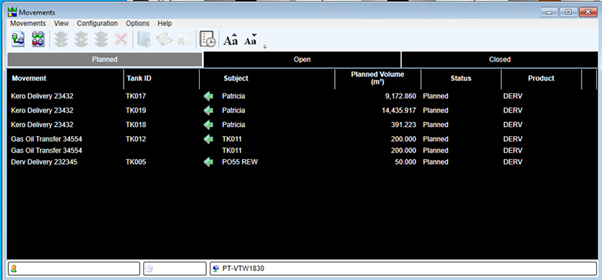

The movements package opens at a summary screen, where movements in various states are shown, planned movements are awaiting execution, open movements are in progress and closed are work that is done.

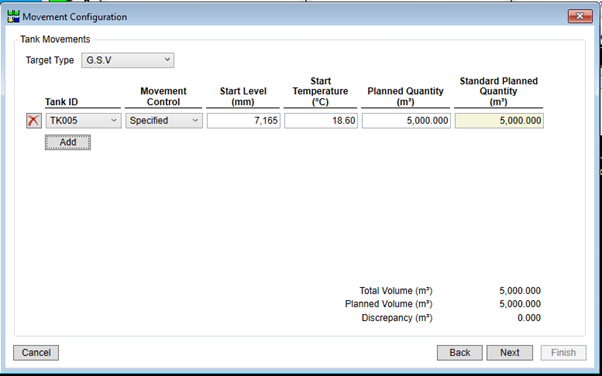

There are two methods for creating movements. The main method is via a movement “wizard” that guides the operator through the process in a step-by-step fashion. Unlike the simple movements more complex movement scenarios are possible: a ship receipt into multiple tanks, making a blend from multiple source tanks, long running jobs feeding and receiving a process, or managing recirculation to mix a tank.

The system eliminates many of manual calculations operators need to do, that are a frequent source of errors, when planning movements. Targets can be expressed as volumes, weights, standard volumes or observed volumes according to your needs.

Housekeeping Movements

Having worked in tank gauging for many year MHT are aware that although the big “headline” ship receipts attract the most attention, the majority of movements are more mundane. Simple housekeeping; consolidating inventory into one tank, draining water, all these movements require the same level of care as they have the potential to be as dangerous as the big movements.

A quick movement configuration method is provided to make a simple tank-to-tank transfer a snap to configure. The same level of safety and monitoring is provided on these movements, it is just that many of the options are hidden behind defaults. It really is easier for an operator to apply the site rules than deviate from them.

Movements can be monitored either through the summary window, or through a movement window. If the movement is a multi-tank movement: suppose the ship must discharge into many tanks, then all the components of the movement are shown together in one place, allowing each tank to be opened and closed as and when needed.

The net flow from the ship is calculated from the individual flows from the tanks as is the accumulated volume moved and the volume remaining to be moved. This is invaluable in helping the operators understand where they are with a large, complex movement, where delays can result in demurrage charges.

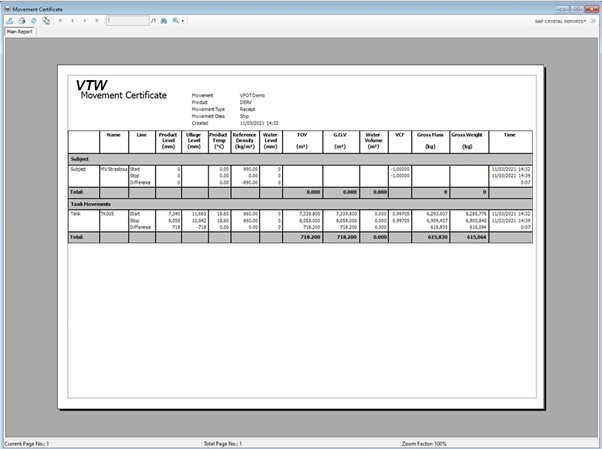

Completion and Reporting

In many circumstances the movement is completed once the pumps are turned off and the valves are closed. When a custody transfer has occurred there are often more steps to follow in order to close out the movement. The Full Movements package supports the entry of manual dip values and pipeline adjustments after the tanks have settled, allowing accurate assessment of the inventory changes that have occurred.

These finalised data are then used to generate reports to document the process. The report format is defined by a Crystal Reports template that can be customised to match corporate styles.

Give users the ability to plan and monitor tank movements

Give users the ability to plan and monitor tank movements Allow target values to be calculated

Allow target values to be calculated