MHT is pleased to announce that INDEX has officially signed off the project handover for the Phichit and Lampang sites. These sites are part of the pipeline project to increase infrastructure in the North of Thailand, creating growth of all industries in that area and relieve roads of dangerous traffic. These former greenfield sites are now managing their truck loading operation using Terminalvision and Queuing, and their inventory with Tankvision Professional. The handover is significant because the customer has plans to start work on a 3rd site in 2021.

This is an important development as MHT are helping these sites achieve “zero loss” by the combination of the tank gauging and terminal automation software. Incoming amounts from the pipeline system are recorded and truck loadings are automatically registered. Both the input and output from the site can then be reconciled against the physical stock at the beginning and the end of the transaction period. Reports can then be generated and allow either confirmation of a smooth operation or to highlight irregularities.

The control room at FPT, featuring Terminalvision software.

aBOUT THE PROJECT

In the early 1990s the “Fuel Pipeline Transportation Limited (FPT)” was created to build a pipeline system in Thailand.

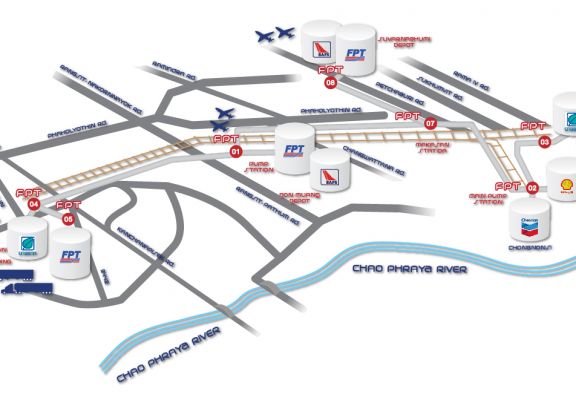

The first projects in 1994 were in the greater area of Bangkok connecting three refineries in Bangkok and Donmuang Airport and since 1996 Suvarnabhumi Airport. The latest extension projects connect two terminals in Pichit and Lampang and the pipeline throughout is based on demand at terminals Pichit and Lampang. Additional terminals are in a draft state connecting to Myanmar. The pipelines are buried underground, mostly along roads with the depth of around 1.50 metres and an outside diameter of 14 inches. The pipelines have an average thickness of 8 mm. The pipeline is a multi-product pipeline, where different fuels can be transported. Amounts arriving at that terminals via pipeline are about 300m3 per hour, the equivalent of 10 trucks arriving every hour and unloading their fuel.

FPT’s Pichit terminal at the end of the pipeline is serving several oil companies with a planned capacity if over 2 million litres for daily truck loading. Products stored include regular and premium gasoline, diesel and jet fuel.

Diagram showing the pipeline.

How terminalvision is playing its part

Terminalvision is a flexible Terminal Automation System which gives you total control over product movement and stock reconciliation. Since launching in the UK 2011, Terminalvision has grown worldwide, allowing our customers to transport bulk liquid with the highest efficacy.

The latest features on the software enhance digital transformation by meeting the latest demands in the industry. Our mission is to continue making the transportation of bulk liquid as efficient as possible. Bulk liquid distribution whether by road, rail, air or water requires tight controls to ensure safe, secure and efficient operations. Every site has its own unique set of circumstances that brings with it challenges commercially, environmentally, and logistically. A “one size fits all” approach to terminal automation is impossible. However, we can offer scalable standalone stations for a small depot, or a full client-server system for larger sites, with multiple operator stations.

Terminalvision offers flexibility in its application, supporting many of the leading batch controllers. Access control devices and identification methods are also available to ensure your product is kept safe. Terminalvision provides full stock management and reconciliation, with a comprehensive set of reports including BoL to ADR standards. It enables total site control and overview, allowing operators to access details of all gantries, loading arms, vehicles, drivers, and product in use on-site with ease.

kiosk and queuing features

The terminal automation system was specifically designed to cater to the needs of a terminal serving multiple oil companies and independent companies carrying the oil to different locations. Sites like the ones in Phichit and Lampang need a structured queuing system to manage their traffic. Queuing evaluates the workload on the site in real-time and produces an “optimum” plan to get the trucks through the site as efficiently as possible. The MHT Queuing software is flexible in that you can define what “efficiency” means to your site: maximum throughput of product, minimal amount of delay for drivers, even favouring certain customers over others.

The Kiosks and queuing provide load planning and optimisation features with automated notification by SMS and electronic document delivery making operations transparent to stakeholders. API’s allow integration with ERP systems to allow an accurate exchange of transactions and orders, ensuring that the products dispensed are subject to financial controls.

The touch screen kiosk allows drivers without the assistance of terminal operators to set up their scheduled loads, safely within all limits of trucks and allowed grades of product. Displays are presented in both Thai and English. The validity of driver licenses, safety inspections of trucks or other safety constraints are checked at that time too. The driver is assigned a queuing number, making sure that they get the right product into the compartments of the truck, and presented with a printed Fill Advisory Note . A big screen shows the individual queues and calls drivers to the loading bay at the optimum time. Operators optionally keep full control on who is loading in what location, with the ability to reschedule.

Additional manual inspection of the truck compartments before and after loading by terminal staff gives a second safety layer and it is documented in the system. This ensures a smooth distribution of fuels to the customers.

Kiosk and Queuing in use on site.